Detailed Selling Lead Description

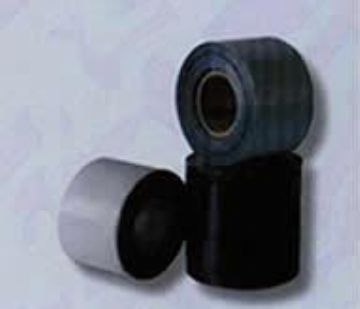

Polyethylene tape anticorrosion coating system is brought by the anti-corrosion protection zone, zone - I, primer combination. Adhesive tape from polyethylene membrane, a layer of thermal compound with butyl rubber as the main adhesive layer, the band Squeeze into anti-corrosion materials. It has insulation and good preservative effect excellent mechanical strength, impact resistance, resistance to aging, absorbing small, convenient, health and safety, a wide range of application, long life and other characteristics. Widely used in oil, gas, petrochemical, power, metallurgy, city gas pipeline networks, water pipeline project and other facilities with metal pipe outside the preservation efficient, long-life. widely used in petrochemical, natural gas, coal, and other engineering overhead buried metal pipe outside preservation. 1, the gel thickness uniformity, a good adhesive sealing performance. 2, and the gel matrix bonding, or deposited in the construction process unglued phenomenon does not exist. 3, good heat aging, anti - ultraviolet capability. 4, high tensile strength, elongation at break appropriate, the convenience of the mechanical and manual winding. 5 varieties, specifications, full color, including the preservation zone (within the band), the protection zone (outer), I-band, Anticorrosive paint and other construction equipment. 2. the main technical indicators project name units PE-T100 (belt) PE-T200 (outer) PE-T30 0 (I-band) No.-T-136 T-140 T-150 T-180 T-240 T-250 T -265 T-360 T-380 T-3150 color-black or other black, white, Other black or yellow or other tape basement membrane thickness of 0.21 mm thickness .23 .25 .40 .25 0.27 0.45 0.30 0.30 0.50 0.15 mm thickness of the gel 0.17 0.25 0. 40 0.15 0.23 0.20 0.30 0.50 Total 1.00 0.36 0.40 mm thickness 0 .50 .80 .40 .50 .65 .60 0.80 1.50 Tensile Strength N / cm ≥ 50 ≥ 50 ≥ 50% elongation ≥ 300 ≥ 300 ≥ 300 Primer peel strength of steel N / cm ≥ 25-≥ 25 pairs of tape back build N / cm 5-10 dielectric strength kv / ≥ 40 mm volume resistivity Ω.m " 1x1012 water vapor transmission (24h) membranes ≤ 0.1 ≤ 0.2 ≤ 0.1 real heat aging 2400% h post-mortem "UV resistance 25 aging 168 h ≥ 80% ≤ 0.1% water absorption temperature 5-5 ° C 0