Detailed Selling Lead Description

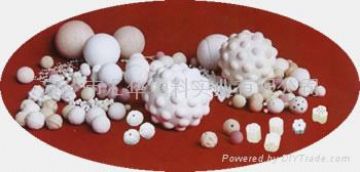

● The inert alumina ceramic ball is broadly utilized as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas, for example, petroleum, chemical industry, chemical fertilizer, natural gas, and environmental protection etc. There are lots of merits for it, for instance, the stronger resistance to high temperature and high pressure, lower ratio of the moisture absorbing, more stable chemical properties, and so on. It is capable of enduring the corrosion of acid, alkali, and organic solvent. In addition, it can also bear the rapid transitions of temperature during the operation. In fact, its principal functions are to accelerate the distribution of gas or liquid, and support or protect the active catalyst, which especially has the relevantly lower mechanical strength.

This product, which had been developed by our group company, had gained the award of excellent new product and the prize of the science and technology improvement of Jiangxi province in 1988. In the same year, this product entered the national honor roll of the excellent new product. In 1990, it gained the national certificate of the science and technology achievements. In 1996, it also got the provincial certificate and the golden prize of the famous brand product. Of late years, it has always been recommended by SINOPEC. Since it entered the market, all circles of customers had realized that its properties and effects are the same as the foreign products, and some of the technological index has surpassed the same foreign products.

●Embossed Slot Perforated Efficient Ceramic Ball (Patent No:2005201337860) is a new product developed on the basic of KK perforated ceramic ball by slotting on the sphere, and by forming lot of knobs uniformly on the sphere of the ball. It can increase the surface area and free volume, and decrease the bulk density, It can increase flux of the fluids and decrease the resistance of the system. As a new efficient support and covering material of catalyst. It can be widely used in oil refinery,chemical,fertilizer,natural gas and environmental protection industries.

● KK Perforated Ceramic ball is developed on the basis of inert ceramic ball. It has an adequate mechanical strength, chemical and thermal stability as the normal inert one; ferthermore it has higher dispersion and flux of the fluids, more surface area and lower resistance resulting from the perforated holes on the ball body, As a new efficient support and covering material of catalyst, it has been widely used in oil refinery, chemical, fertilizer, natural gas and environmental protection industries since put into market.

● MH Porous Ceramic Balls is also called filtering balls. It is made by make 20~30% pores inside the inert ceramic balls. Therefore it can be used not only for supporting and covering the catalyst, but also for filtering and eliminating the impurities of grain, gelatin, asphaltine, heavy metals and iron ions of less than 25μm. If the porous ball is set on the top of a reactor, the impurities fail to be eliminated in former process could be adsorbed in the pores inside the balls, thereupon protect the catalyst and prolong the operating cycle of the system. As the impurities present in the materials are different, the user can select the product by their sizes, pores and porosity, or if necessary, add molybdenum, nickel and cobalt or other active components to prevent the catalyst from coking or poisoning.

●SW Activated ceramic ball is a new support material for catalyst. It is processed by adding a small amount of transition metal oxide into the inert ceramic ball. It preserve the property of high - temperature resistance and strength of the inert ceramic ball, in addition, it has adequate catalytic activity when used in the process of olefin hydrogenation. If been set on the top of catalyst bed in the reactor, the activated ceramic ball can make the olefin in t